ABOUT MAGNESIUM DIES

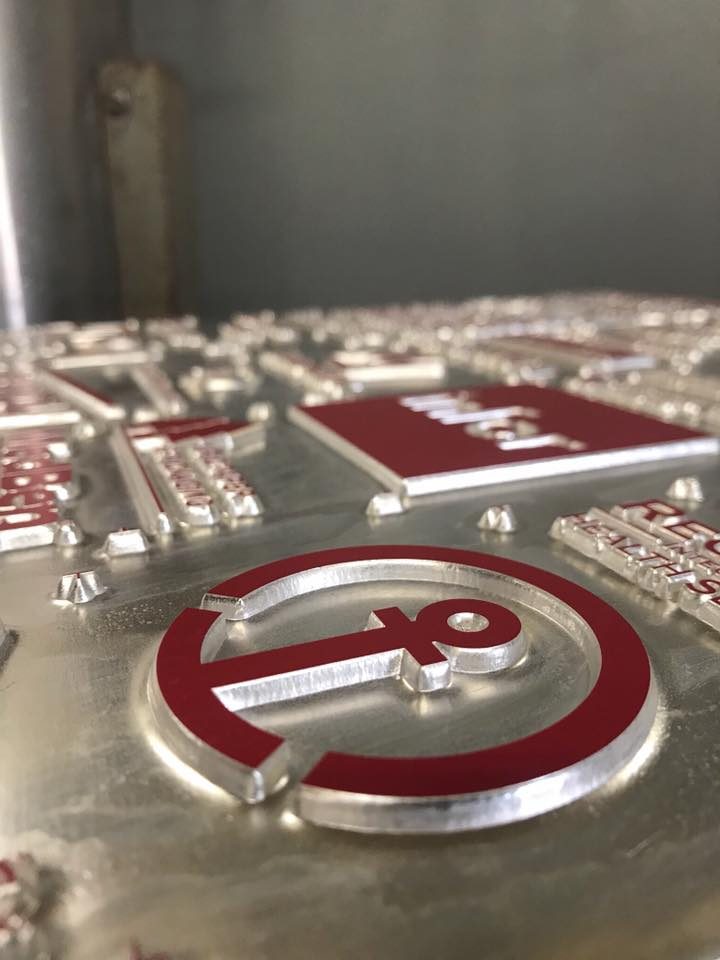

OR PRINTER USA offers a full range of magnesium dies for foil stamping, debossing, letterpress printing plates, and custom applications. Magnesium dies can be used for a variety of different products, including everything from promotional products to annual reports, decals to rubber stamp masters, menu covers to automotive aftermarket, and ribbon awards to medical recovery devices.

Types of Magnesium Dies:

- 16 gauge (.064″)

- 80 thousandths (.080″)

- 11 point (.153″)

- ¼ inch (.250″)

- 3/8″ (.375″)

Several important factors combine to determine whether magnesium, copper or brass is right for your application. Choosing magnesium, when appropriate, can yield cost savings for your customers and speed up turnaround without sacrificing quality. Magnesium is best used on smaller areas with smoother papers, while copper is typically beneficial for larger areas, more heavily textured papers, and extra long runs.

ABOUT COPPER DIES

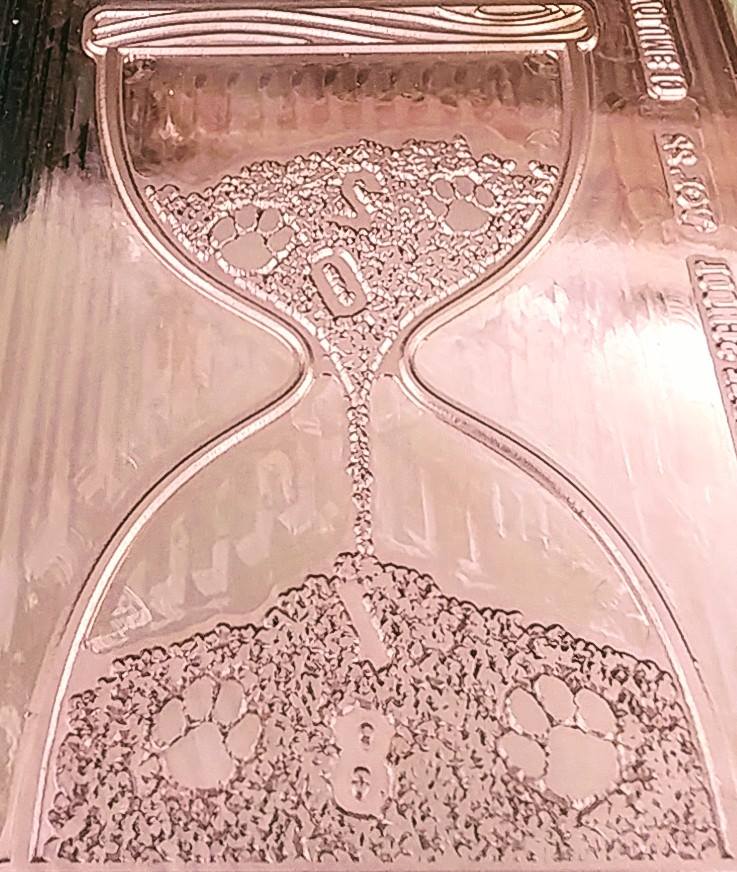

Copper dies are used in place of magnesium dies when a certain impression length is exceeded. This will vary depending on the type of substrate you are stamping on. Press runs of a million or more foil stamping impressions can be achieved with a photoengraved copper die.

Copper is an excellent heat conductor and retains heat longer than magnesium, which means that when the dies are heated on press, copper dies will have far less heat expansion. This is especially important when foil stamping on high-speed equipment, where the speed and action of the press are more likely to cool the temperature of the die. If stored properly, copper dies can be reused for long periods of time.

Die types available:

- Single Level Embossing

- Single Level Debossing

- Foil Stamping

- Letterpress Printing Plates (wood mounted or unmounted)

- Intaglio (Engraving)

Metal Thicknesses Available:

- 16 gauge (.064″)

- ¼ inch (.250″)

he types of engravings for embossing and foil stamping products varies as much as the type of paper used. Brass dies for embossing and combination foil stamping include a range from flat stamping foil images to multi-level, sculptured designs. Brass is a superior material for both machine work and hand sculpting, and is the best choice for combination foil stamping and embossing designs.

Designing Your Brass Die

The process of making a sculptured embossing or combination die begins with the customer and engraver during the design stage.

Terms like raised round, raised roof, deboss flat and many more are discussed before the die is started. These terms are used to describe the desired look you would like to achieve.

The type of stock is a very important decision that is made in the design stage. Your choice of stock, paper weight, thickness, color and finish will all have a great impact on how the foil, embossing or combination foil stamping will look.